pressure vessel impact testing|ferritic flange impact testing : suppliers welding procedure used on each vessel or group of ves-sels as defined in (3) below. The vessel impact test plate shall be from one of the heats of steel used for the vessel or group of . In Miragine War, become just such a commander and choose from 16 different units, from the strong knights adorned in heavy armor to restless zombies and even vampire lords, to send onto the battlefield to win the war! As the player, your objective in Miragine War is to defeat your enemy and win the war by killing the enemy units and reaching .

{plog:ftitle_list}

web5 de fev. de 2024 · 6. Construção de relacionamentos. 7. Paciência e persistência. 1. Compreensão de seu caráter. Criar um personagem completo e crível é o primeiro passo para melhorar a interpretação de papéis no GTA RP. Comece desenvolvendo a história de fundo, os traços de personalidade, os pontos fortes e os pontos fracos de seu personagem.

impact testing mdmt

test e 250 bottle

flange impact testing requirements

Based on the ASME impact test requirement, you need to make assessment to see that either your pressure vessel is exempted from impact testing, or you need to carry out the test. There are 4 steps for impact test exemption assessment.This one-day MasterClass provides an in-depth review of the rules and application of the ASME Section VIII, Divisions 1 & 2 code rules for toughness requirements associated with a pressure .3.11.2.2 Required Impact Testing Based on the MDMT, Thickness, and Yield Strength. (a) If the governing thickness (see 3.11.2.3(b) at any welded joint or of any nonwelded part exceeds 100 .

Impact strength is measured using a Charpy or Izod test in which a machined specimen is impacted by a swinging hammer. Topics: Impact testing, Brittle fracture, Impact strength, .welding procedure used on each vessel or group of ves-sels as defined in (3) below. The vessel impact test plate shall be from one of the heats of steel used for the vessel or group of .Equipment Directive (PED) and the ASME Boiler & Pressure Vessel Codes, they assure the production of safe pressure equipment. . These are the EN requirement for elevated temperature proof testing, the EN requirement for a minimum absorbed energy impact test value for all pressure equipment materials, and the ASME requirement for lateral .

This is a standard test called the Charpy V-notch (CVN) impact that enables a pressure vessel designer to know the limitation of metals at lower temperature service. Lower energy for failure means brittle fracture conditions.Impact strength is measured using a Charpy or Izod test in which a machined specimen is impacted by a swinging hammer. Topics: Impact testing , Brittle fracture , Impact strength , American Petroleum Institute , Brittleness , Crack propagation , Failure mechanisms , Fracture toughness , Hammers , Low temperature , Pressure equipment , Temperature

jak 2 blood test bottle

Temperature requirements for ASME code cryogenic pressure vessels and weld materials per ASME Section 8. When impact test. 708-425-9080. Services > > > > Products > > > > > > . One might think this is accomplished by using the impact test data from the Vessel (Production) Impact Test coupons, however there are additional requirements and .2008 ASME Pressure Vessels and Piping Division Conference July 27-31, 2008, Chicago, Illinois PVP2008-61215 1 IMPACT TESTING OF STAINLESS STEEL MATERIAL AT COLD TEMPERATURES1 Dana K. Morton Robert K. Blandford and Spencer D. Snow Idaho National Laboratory P.O. Box 1625Fig. UCS-66 Impact test exemption curves [Ref: ASME Sec. VIII Div.1] ASME Sec. VIII Div.1: UCS-66(a) Unless exempted in UG-20(f), Fig. UCS-66 shall be used to establish impact testing exemptions for steel listed in part UCS. Impact testing is checked for the combination of minimum design metal temperature and governing thickness of the part.the extent required by the procedure test (seeUCS-67 and UHA-51). (3) Number of Vessel Impact Test Plates Required (-a) For each vessel, one test plate shall be made for each welding procedure used for Category A and B joints, unless the vessel is one of several as defined in (-b) or (-c) below. In addition, for Category A and B joints the follow-

The manufacturing of some parts that require a specific level of toughness, such as ship hull components or pressure vessels, benefits greatly from impact testing. Impact testing helps ensure that these components are made to the required specifications and are safe for use. It guides the design and optimization of components and structures. ASME Code Section VIII Div 1 exemption rules for ASME Impact Test Requirements: There are specific rules in the ASME Code for exemption from ASME Impact Test Requirement. This test is very expensive, so pressure vessel manufacturers are trying to be exempted from this costly test. You need to follow the following clauses to make.Pressure equipment that is covered by the PED includes pressure vessels, pressure accessories, piping, steam boilers, safety . The conformity assessment procedure provides inspection and quality assessments depending on the environmental impact and level of risk if equipment failure should occur. Steps include: . Testing and Certification .

The chemical composition of the test steel (SA508 Gr.4N) with elemental composition as per ASME boiler and pressure vessel-section – materials–SA-508/SA-508M specification 17. The chemical .

But after 1987, the pressure vessel code added rules including eliminating the impact testing exemption at −29 °C (−20 °F) and implemented a minimum design metal temperature (MDMT). The MDMT of a vessel is the minimum metal temperature in which the vessel can sustain its full design pressure without having to be impact tested.

The hypervelocity impact testing reported herein has been conducted on a series of non-flight, full scale COPV provided by NASA’s International Space Station program. To maximally illustrate the effects of MMOD impact damage to pressurized COPV, the test articles have been subjected to hypervelocity impact in the absence of shielding .

Explore the essentials of pressure vessel testing, its significance, and various methods. Ensure safety and optimize performance with RedRiver's insights. HOME; About . and other external factors can impact the vessel’s integrity. Consider implementing protective measures, such as coatings, insulation, or corrosion-resistant materials, to .

The second type of test article is a pressure vessel. Test articles are fabricated at two thickness, 0.05 and 0.08 inch, to formulate scaling relationships in analyses of the test results. The vessels have an inner diameter of 20.75 inches and a length of 48 inches. The endcaps are flat to facilitate manufacturing and test fixturing. The vessel impact test plate shall be from one of the heats of steel used for the vessel or group of vessels For Category A joints (longitudinal seams), the test plate shall, where practicable, be welded as an extension to .the impact test temperature). For pressure vessel attachments that are exposed to tensile stresses from internal pres-sure (e.g., nozzle reinforcement pads, horizontal vessel saddle attachments, and stiffening rings), the coincident ratio shall be that of the shell or head to which each component is attached. [See 3.11.2.4(b)]. With nearly 50 years of performing various destructive tests for both government and industry and through our support of COPV Standards Development, our Composite Overwrap Pressure Vessel (COPV) group can perform destructive testing on both simple and complex systems with difficult-to-measure pressure vessel attributes.We can test on single and .

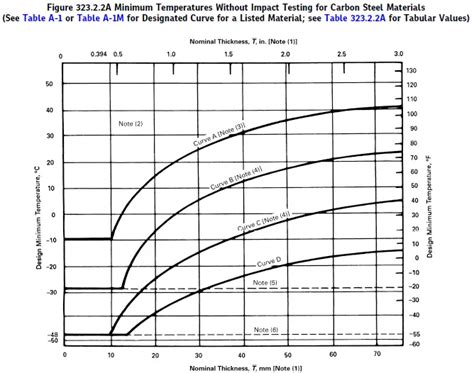

Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, the curve in Figure 323.2.2A of ASME B 31.3 .

This is a standard test called the Charpy V-notch (CVN) impact that enables a pressure vessel designer to know the limitation of metals at lower temperature service. Lower energy for failure means brittle fracture conditions.A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different . current standards dictate the use of steel with a high impact resistance, especially for vessels used in low temperatures. . pressure is usually 1.5 times working pressure, but DOT test pressure for scuba cylinders is 5/3 (1.66) times .ASME’s Boiler and Pressure Vessel Code (BPVC) | 2013 Pressure Vessels, continued Division 2: API 579-1/ASME FFS-1 – Fitness-For-Service Three Standards from the B1 Series on screw threads Nine Standards from the B16 Series on pipe flanges and fittings Four Standards from the B18 Series on hex bolts B36.10M -- Welded and Seamless Wrought

Hypervelocity impact testing of a pressurized composite overwrapped pressure vessel and comparison to numerical analysis . the use of high strength-to-weight Composite Overwrap Pressure Vessels .The Pressure Systems Safety Regulations 2000 (PSSR) relates to pressure systems for use at work. Their aim is to prevent serious injury from the hazard of stored energy and scalding effect of steam as a result of the failure of a pressure system consisting of pressure vessels and/or pipework, along with associated protective devices.. The main reasons for pressure-related .

For instance, Lasn et al. [7] used such a modeling approach to study the sensitivity of the residual burst pressure of thin pressure vessels (2.1 mm thick) to material strength properties when subjected to impact in the cylindrical part of the vessel. The fracture toughness of the composite and the hoop layer tensile strength were identified as the most important .

strength of composite pressure vessels. Additionally, test and evaluation on composites that have been impact damaged is in progress so that models can be developed to estimate damage tolerance and the degradation in static strength. Nomenclature . WSTF: White Sands Test Facility . CPV: Composite Pressure Vessel . PFA: Progressive Failure Analysis

(Page 1) Despite the prevalence of pressure vessels in the chemical process industries (CPI), a clear understanding of the basis-of-design responsibilities involved in designing, fabricating and repairing such a device remains elusive. . For carbon steel and low-alloy vessels, the requirement for Charpy impact testing can be determined in .

Assistir Friends Temporada 2 no Netflix, FoxPlay, Claro Video, etc.? Veja onde assistir todos os episódios online agora.

pressure vessel impact testing|ferritic flange impact testing